A Taxonomy of EC&M Insulators ...Mastering Your ABC's

by Howard Banks

Reprinted from "Crown Jewels of the Wire", January 2003, page 27

LlGURTA, AZ February 10, 2001. Climbing out of a dry wash, I glance to my

left at a giant saguaro cactus in the distance. To my right, looking into the

setting sun, I see the faint outline of an ancient trail through Sonoran Desert.

"What am I doing here?", I ask myself. Only seven weeks since knee

surgery, I am too unsteady on my feet to be dodging rocks and rattlesnakes.

Weighing heavy on my mind is an all night drive back to Oregon. "It's

4:30 PM. Let's see, leave at 5:00. Drive over 1,000 miles. Yeah, maybe I'll be

home by noon tomorrow."

Bill Ostrander, Scott Morrell and myself were in

San Diego the day before to look at purchasing an insulator collection. Today,

we attended an insulator swap meet in Yuma next to the historic Arizona

Territorial Prison. The meet was fun, and we were introduced to many collectors

we had corresponded with but never met before. Among them was Tom Katonak, who

invited all who were interested to take this walk in the desert to look for a

long lost military telegraph line. Built in the mid 1870's. Reportedly used

EC&M's. "Ahh! Now I remember. That's why I'm here."

I decide to

turn to my right. Up that trace of a trail. As I squint facing the last rays of

the sun, something catches my eye. In my heart I know instantly what it is. In

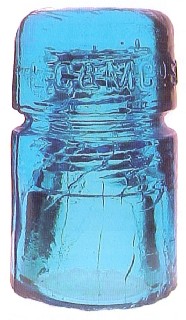

my head, I hardly dare to believe it! Sparkling like a sapphire gemstone on the

desert floor, a shattered insulator transfixes me. Not just any insulator. An

EC&M. And not just any EC&M. A spectacular blue one. It's the color

collectors have nicknamed, "Arizona Blue". I pick up the pieces. They

sparkle in my hands like jewels in a crown. I call out that I've found the line.

In the next half hour, collectors find four more pole settings; pieces of three

more "Arizona Blues", and a broken Brookfield Cauvet's Patent (CD 133)

In the nearly two years since this initial find, more than two dozen collectors

have hiked stretches of the elusive military line near Ligurta. To my knowledge,

no one has found a whole insulator. I've been back twice. And the appeal of

EC&M's will keep me returning for a long time to come.

HISTORY

That appeal is as many faceted as a gem stone. EC&M insulators represent

history you can hold in your hands. The Electrical Construction and Maintenance

Company was organized in San Francisco in December 1870. In that context, the

West is still wild. Barbed wire hasn't been perfected. The Transcontinental

Railroad is only a year old. The shoot out at the OK Corral? Eleven years in the

future. And General George Armstrong Custer is still hoping to find more

Indians.

The military telegraph line to Yuma through the desert was only in

service for a couple of years before being relocated along railroad tracks. Yes,

I'll keep going back to look for a whole EC&M. Custer got his wish; maybe

I'll get mine.

TAXONOMY

Another facet in the fascination of EC&M's is their variety. In

the July and August issues of Crown Jewels in 1974, insulator collector Fritz

Kettenburg identified 8 basic mold styles of EC&M insulators. He named the

mold styles by the letter designations A through H. Those 8 basic styles were

all that were known until the mid 1990's when new varieties began to surface. In

this issue of Crown Jewels, I present six additional mold styles. I'll continue

Kettenburg's alphabetical listings, extending the list through mold style N.

Each mold style is different from the others in ways that are consistent,

observable and measurable. The mold styles, therefore, are classified by the

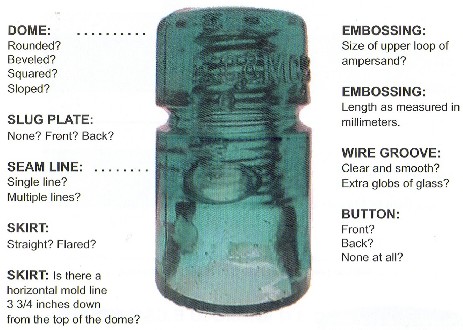

following taxonomy:

DOME Traditional dome shapes are "round", "beveled" and

"squared". Some recent additions are better described as

"sloping".

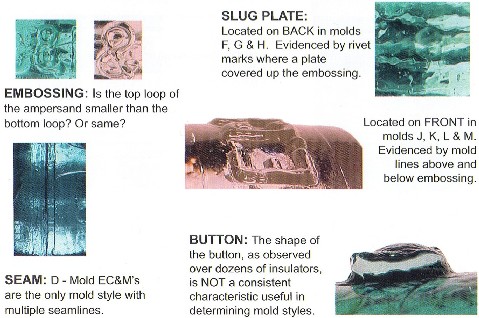

SLUG PLATE A "slug plate" is a strip of soft metal

added to a mold. In some instances of historic bottle production, the slug plate

contained the embossing. In this way, a glass manufacturer could use the same

mold to produce bottles for different customers simply by changing the slug

plate containing their name. Among traditional EC&M's, only mold styles F, G

& H have a slug plate.

"I have a BIG BUZZ

for insulators!"

But in those molds, the slug plate is on the opposite side of the insulator

from the embossing, and appears to have been used to cover up a mistake where

the embossing had been carved into the mold upside down. Conversely, most of the

recent additions feature embossing created by a slug plate. In fact,

"mold" lines above and below the embossing are the quickest way to

identify mold styles J, K, L & M.

EMBOSSING LENGTH The length of the embossing is consistent within each mold style, but varies

significantly from one mold style to another. The length ranges from 61

millimeters to 77 millimeters. Proportionately, the embossing is 20-percent

longer on some mold styles than others. For the purpose of this report, length

is measured in millimeters. Differences in length of a couple of millimeters can

be attributed factors ranging from the temperature of the mold when the glass

was poured, to the device being used to take the measurement, to shaky hands

when measuring. In my opinion, consistent differences of four or more

millimeters raises the possibility of a separate and distinct mold.

AMPERSAND The shape of

the ampersand itself can be used to distinguish some molds from others. On most

mold styles, the upper loop on the ampersand is approximately the same size as

the bottom loop. But on a few styles, the upper loop is noticeably smaller than

the bottom loop. Among traditional mold styles, only B molds have a small upper

loop. The characteristic is found on the recently discovered J mold style. It's

also found on the skirt-embossed I molds.

WIRE GROOVE Extra globs of glass

consistently placed in specific locations are characteristics found on D and

H

molds.

SEAM LINE D molds show three parallel seam lines, as if the mold was made out of

sheet metal like a stove pipe. As a result, D's are nicknamed "tin

molds".

SKIRT SHAPE Compared to the "straight" skirt of most molds, styles

A

and F have "flared" skirts. On both A molds and F molds, the diameter

of the insulator is 9 millimeters wider at the base than mid-way up the skirt.

EXTENDED SKIRT Mold styles E, F, G and H have an extra "mold" line that runs

horizontal around the skirt of the insulator near the base. This creates the

impression that the mold was extended to create taller insulators. The mold line

for the extended skirt is found 3-3/4 inches down from the top of the dome. Be

aware that some individual insulators in these mold styles are so short that

there is no evidence of the extended skirt.

HEIGHT The height of an insulator is NOT a factor in identifying mold

styles. Even "extended skirt" styles are sometimes so short that their

horizontal mold line is non-existent. Traditional mold styles range from less

than 3-3/8 inches tall to 5-1/8 inches. A few examples from recent discoveries

are even taller.

BUTTON The "button" of glass on most EC&M's is an

important characteristic in identifying mold styles. A molds have no button.

Other molds have a button on the front. Still others on the reverse.

SHAPE OF BUTTON Contrary to previously published studies of EC&M insulators, I do NOT

find the shape of the button to be a consistent trait useful in identifying mold

styles. It was traditionally reported that B molds have a "squared"

button. However, in observing hundreds of EC&M's, just as many B mold

insulators have a "rounded" button as "squared" buttons.

OTHER CHARACTERISTICS Additional observations can be taken of consistent traits on EC&M's.

Included are the exact location of the button; shape and position of the glass

bead at the top of the pin hole; shape and size of the threads, and

circumference of the insulator. While measurable and distinct from one mold

style to another, these characteristics will not be described here. Many

collectors believe certain EC&M styles are of recent production. Therefore,

some key information is being withheld deliberately to trip up potential

imitators.

E.C&M CO. S.F. TAXONOMY

Taxonomy is the classification of EC&M insulators based on

observable,

measurable, and consistent mold characteristics. Some key areas of

measurement are illustrated here.

E.C&M co. S.F. TAXONOMY DETAILS

|

A - MOLD E.C&M CO. S.F.

DOME: Rounded

EMBOSSING: Large upper loop on ampersand.

EMBOSSING is 77 millimeters long.

SLUG PLATE: None

WIRE GROOVE: Clean

SEAM: Single line.

SKIRT: Flared.

BUTTON: NONE!

A - Mold EC&M's are quickly identified by the lack of a button on the

front or back.

COLORS: Cobalt, ink blue, emerald green, greens, olive green, olive amber,

and aqua shades. Collectors generally agree that aqua A-Molds are rarer than

those found in cobalt blue.

|

|

|

|

B - MOLD E.C&M CO. S.F.

DOME: Squared.

VARIETY ONE: Smooth dome, no "hash" marks.

VARIETY

TWO: Two "hash" marks on dome perpendicular to mold line.

EMBOSSING: Small upper loop on ampersand.

EMBOSSING:

VARIETY ONE: 64 millimeters. VARIETY TWO: 69 millimeters.

SLUG PLATE: None.

WIRE GROOVE: Clean.

SEAM: Single line.

SKIRT: Straight.

BUTTON: Back.

COLORS: Aqua, greens, yellow green, emerald green, teal green, amber shades,

sapphire blue, cobalt blue.

B - Mold EC&M's are easily identified by the small upper loop of the

ampersand, and no slug plate front or back.

|

|

C - MOLD E.C&M CO. S.F.

DOME: Beveled.

EMBOSSING: Large upper loop, on ampersand.

EMBOSSING is 75 millimeters long.

SLUG PLATE: None.

WIRE GROOVE: Clean.

SEAM: Single line.

SKIRT: Straight.

BUTTON: Front.

C - Mold EC&M's are quickly identified by the beveled top, button on the

front, and no extra glass in the wire groove.

COLORS: Green shades dominate this mold style, including apple and lime

greens. There are also aquas, and the exceptionally rare true TEAL coloration as

shown in this example.

|

|

|

|

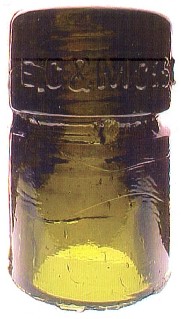

D - MOLD E.C&M CO. S.F.

DOME: Beveled.

EMBOSSING: Large upper loop on ampersand.

EMBOSSING is 77 millimeters long.

SLUG PLATE: None.

WIRE GROOVE: Extra glass under the letters "M" and "C".

SEAM: Three adjacent mold lines.

SKIRT: Straight.

BUTTON: Front

D - Mold EC&M's have been nicknamed "Tin Molds" because their

three mold lines gives an appearance of the mold having been made of sheet

metal.

COLORS: Aqua, blue, ink blue, cobalt blue, green shades.

|

|

E - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: Upside down!

SLUG PLATE: None.

WIRE GROOVE: Clean.

SEAM: Single line.

SKIRT: Flared. Extended skirt with horizontal seam line 3-3/4 inches down

from the top of the dome.

BUTTON: Front.

E - Mold EC&M's are among the rarest of all CD 123's. Only a handful are

known. A couple were dug in California in the 1960's. This example was dug in

British Columbia in the mid-1980's.

COLORS: Aqua, green, emerald green.

|

|

|

|

F - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: Large upper loop on ampersand.

EMBOSSING is 67 millimeters long.

SLUG PLATE: Reverse.

WIRE GROOVE: Clean.

SEAM: Single Line.

SKIRT: Flared. Extended skirt with horizontal seam line 3-3/4 inches from top

of dome.

BUTTON: Back.

F - Mold EC&M's are another scarce mold variant. Flared skirt EC&M's

are always in demand.

COLORS: Aqua, green, emerald, olive, ink blue, light cobalt, dark cobalt and

Arizona blue.

|

|

G - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: Large upper loop on ampersand.

EMBOSSING is 68 millimeters long.

SLUG PLATE: Reverse.

WIRE GROOVE: Clean.

SEAM: Single line.

SKIRT: Straight. Extended skirt with horizontal seam line 3-3/4 inches down

from the top of the dome.

BUTTON: Back.

G - Mold EC&M's are easily identified by the large upper loop of the

ampersand, the straight skirt, button on the reverse, and extended skirt.

COLORS: Aqua, greens, yellow green, Aurora blue, ambers, sage green, and

purple.

|

|

|

|

H - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: Large upper loop on ampersand.

EMBOSSING is 68 millimeters long.

SLUG PLATE: Reverse.

WIRE GROOVE: Extra glob of glass under letter "M".

SEAM: Single line.

SKIRT: Straight. Extended skirt with horizontal seam line 3-3/4 inches down

from the top of the dome.

BUTTON: Back.

H - Mold EC&M's are easily identified by the extra glob of glass under

the letter "M", in combination with G-Mold characteristics.

COLORS: Aqua, greens, yellow green, sage green, Aurora blue, ambers, &

purple.

|

|

I - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: SKIRT! Embossing is similar to B-Molds with a small upper loop on

the ampersand.

EMBOSSING is 66 millimeters long.

SLUG PLATE: None.

SEAM: Single line.

SKIRT: Straight.

BUTTON: Reverse.

I - Mold EC&M's were found in Sacramento, CA in 1994 at the site of a

toxic waste clean-up. Approximately 10 skirt embossed examples were found among

120 EC&M's recovered. Not to be confused with the find of J, K, L & M

Molds.

COLORS: Yellow green shades, slate blue, & smokey charcoal grey.

|

|

|

|

J - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: Small upper loop on ampersand like a B - Mold.

EMBOSSING is 74 millimeters long, which is much longer than B-Molds.

SLUG PLATE: Located under embossing. Slug plates are not found on B-Mold

EC&M's.

SEAM: Single line.

SKIRT: Straight. No horizontal lines like E, F, G & H Molds.

BUTTON: Back.

J - Mold EC&M's were found in Sacramento, CA in the mid-1990's. A party

to the find declined an invitation to tell the story of the discovery.

COLORS: Peacock blue, clear.

|

|

K - MOLD E.C&M CO. S.F.

DOME: Squared.

EMBOSSING: Larger upper loop on ampersand similar to F, G & H Molds.

EMBOSSING is 63 millimeters long, shorter than F, G & H Molds.

SLUG PLATE: Located under embossing. Slug plates on F, G & H Molds are on

the reverse.

SEAM: Single line.

SKIRT: Straight. No horizontal lines like E, F, G & H Molds.

BUTTON: Back.

K - Mold EC&M's were found in Sacramento, CA in the mid-1990's. A party

to the find declined an invitation to tell the story of the discovery.

COLORS: Purple in fluorescent lighting and pink in incandescent lighting (as

pictured), clear.

|

|

|

|

L - MOLD E.C&M CO. S.F.

DOME: Sloping.

EMBOSSING: Larger upper loop on ampersand similar to C Molds.

EMBOSSING is 61 millimeters long, much shorter than C Molds.

SLUG PLATE: Located under embossing. Slug plates are not found on C Molds.

SEAM: Single line.

SKIRT: Straight.

BUTTON: Front like C & D Molds.

L - Mold EC&M's were found in Sacramento, CA in the mid-1990's. A party

to the find declined an invitation to tell the story of the discovery.

COLORS: Bright green.

|

|

M - MOLD E.C&M CO. S.F.

DOME: Sloping.

EMBOSSING: Larger upper loop on ampersand similar to F, G & H Molds.

EMBOSSING is 64 millimeters long, shorter than F, G & H Molds.

SLUG PLATE: Located under embossing. Slug plates on F, G & H Molds are

found on the reverse.

SEAM: Single line.

SKIRT: Straight.

BUTTON: Back like F, G & H Molds.

M - Mold EC&M's were found in Sacramento, CA in the mid-1990's. A party

to the find declined an invitation to tell the story of the discovery.

COLORS: Bright green, dark green. Tie wire often attached.

|

|

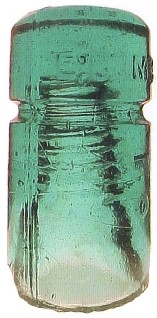

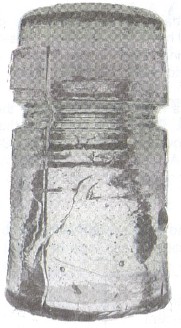

STANDING TALL (OR NOT)

The HEIGHT of an EC&M is not a factor in determining mold styles. Shown

here are two H-Mold EC&M's. At 3-1/2 inches tall, the one on the right is so

short it shows no evidence of the mold style's extended skirt. The one on the

left is 4-1/4 inches tall. Much taller EC&M's exist.

A collector in Oregon owns an extended skirt G-Mold that is 5-1/8 inches

tall.

A published report exists of an EC&M measured at 5-3/4 inches!

MOLD STYLES

A MOLD: A mold EC&M's are easy to identify by one major

characteristic, or the lack thereof. They are the only mold style lacking a

button. It's often speculated that the purpose of the button was to hold the

insulator in place within the mold while the threads were formed. But if true,

then you'd expect to find A mold insulators with stretched and deformed

embossing. But to the contrary, A molds often have much stronger, much more

precise embossing than other styles.

Regardless of the reason for no button, the A mold style seems to have been

short lived. The style is scarce in any color, with examples in aqua glass

believed to be rarer than those found in cobalt blue. Other colors include

emerald green, light green, olive green, olive amber, and ink blue.

A molds are

classic in their overall shape. They have a flared skirt and a rounded dome. At

77 millimeters in length, the embossing is among the longest found in

EC&M's. Added to their rarity, their classic shape enhances their

desirability.

B MOLD: B molds are an easily identifiable group of traditional

EC&M's that are found in two significant varieties. They can be easily

distinguished by the small upper loop on the ampersand. B's are the only

traditional EC&M's to have the small upper loop. They also have a straight

skirt and a squared dome. The button is on the reverse.

Variety One B molds have

a smooth dome, with an embossing length of 64 millimeters. Variety Two B molds

have two short "hash" marks on the dome running perpendicular to the

mold line. They have an embossing 69 millimeters in length. The button can be

squared or rounded on either variety. Were two different molds used to make B's?

Or was a repair or modification made to the mold at some point? More study is

needed.

Overall, B molds are the most common of all EC&M's. This one mold

style comprises perhaps as much as 40-percent of all EC&M insulators known.

It is not surprising, then, that B molds are found in virtually every

traditional EC&M color. Rarer colors include dark ink blue and purple.

C MOLD: Any traditional EC&M with the button on the front is very

desirable, and C molds are no exception. In addition to the button on the front,

C molds have a beveled dome. That is, the top of the dome actually angles

downward to meet the side of the insulator. C's have a large upper loop on the

ampersand; no extra glass in the wire groove; and the embossing is 75

millimeters long.

While most C molds are aqua in color, many depict shades of

green: light green, apple green, yellow green, and lime green. A few have been

found in a true teal green.

D MOLD: This button-on-the-front insulator is unique among all

EC&M's because of having extra mold lines. There's not just one mold line on

this style, but three. They run parallel to each other up one side, over the

dome and down the other side. Collectors long ago compared the mold lines to a

sheet metal mold such as might be found on stove pipe, or the pipe that was used

to carry water to gold mines. D mold insulators were then given the delightful

nickname, "tin molds".

But were they actually made in a tin or sheet

metal mold? It should be apparent that the extreme temperatures of molten glass

would quickly destroy such a flimsy constructed mold. A more logical explanation

might be that D's are the result of a repair to the C mold. Consider the

similarities: They are two of only three traditional styles to have a button on

the front; the only two styles to have a beveled dome; and the embossing is very

similar on both. D's have extra glass in the wire groove under the letters

"C" and "M". However, I own a C mold EC&M that has small

amounts of extra glass in the wire groove under the "C" and

"M". It's exactly like a D mold except for the extra mold lines.

D's

are found in cobalt blue, dark ink blue, light blue, lime green, apple green and

aqua. Some exceedingly short D's have also been found.

E MOLD: It would be nearly impossible to miss an

E mold. The embossing is

upside down! How could that happen? I imagine some hung-over mold maker having a

really bad day at the factory. Or some novice not understanding that molds have

to be reverse images of the final product. Whatever the cause, the boss must not

have been happy with the finished product. Very, very few were made and placed

into service. In the last 40 years, only a handful of E mold EC&M's have

ever been found. A few were located in California, and a couple more were found

in British Columbia.

I got angry the first time I saw an E mold. Oh, I wasn't upset over the

beautiful mossy green insulator. Or even the fact I didn't get a chance to buy

it first. I was upset over the price. The location was a bottle show in

Canyonville, Oregon in February 1968. I was still setting up a sales table,

while my insulator collecting buddy, Charles Fox, was running around to see what

the bottle dealers were offering. He returned proudly displaying an astounding

discovery, an EC&M embossed upside down! I blew my cork when he told me he

paid $40.00 for it. "Forty-dollars?" I screamed. "Chuck, are you

nuts? This will drive insulator prices through the roof. Soon no one will be

able to afford to buy good insulators." At the time it was the highest

price I had ever heard that had been paid for an insulator. (So, now you know

the exact occasion when insulator prices began to skyrocket.)

In addition to

the upside-down embossing, another key characteristic in E molds is the large

extension of glass at the base that adds height to the insulator.

F MOLD: F, G and H molds all appear to be the result of efforts to fix the

upside down embossed E mold. Faint evidence can be seen on F, G and

H styles of

rivet marks and a slug plate. It would appear the upside down embossing was

covered up by a slug plate. New embossing was then carved into the mold on the

opposite side. This would explain why the button on F, G and H styles is not

found on the same side of the insulator as the embossing. The button didn't

move; the embossing did. F, G and H styles also have extended skirts, although

not as prominent as E molds. In fact, in some cases, the insulators are so short

there is no evidence of the extended skirt. This is particularly true of H

molds.

F molds are distinctly different from G and H molds by having a flared skirt,

similar to A molds.

Regarding color, the most frequently encountered cobalt blue

EC&M's are F molds. This style also comes in aqua, green, emerald, ink blue,

and that Arizona blue color that keeps me returning to Yuma.

G MOLD: G mold EC&M's are essentially F mold insulators with a

straight skirt instead of a flared skirt. All other characteristics are

basically the same.

H MOLD: More than likely, H mold EC&M's are

really G mold insulators that depict varying degrees of wear in the mold.

H's

bear all the characteristics of G's, except they have extra glass in the wire

groove both at the left mold line and directly under the letter "M".

It would appear that with ever increasing use, those globs of glass became

larger and larger.

I'd set the standard for what is a G mold and what is an H

mold as follows: If there is any extra glass in the wire groove, no matter how

sleight, the insulator is an H mold. H molds are the second most common

EC&M, after B molds.

G and H molds are found in a wide variety of colors

including aqua, dark ink blue, olive amber, amber shades, green, sage green,

lime green, yellow green, and purple. They also come in a color collectors call

"Aurora Blue". The name comes from a line near Aurora, Nevada that

used a lot of EC&M's in a distinct bluish color.

Chronology:

This ends the section on traditional EC&M mold styles. If I could

speculate on the chronological development of the various molds, it would be as

follows. The A mold with its flared skirt was found unsatisfactory for some

reason, and was replaced by the C mold, which became damaged and, when repaired,

became a D mold. The E mold was created at some point, but due to the

embossing error, was re-tooled to become the F mold. Again, the flared skirt

style was unsatisfactory, so the mold was re-tooled to become the G mold; which,

when it began to wear out, became the H mold. B molds were possibly made through

the entire history of EC&M's, accounting for how common they are. When the

Variety One B molds began to show wear, some slight modifications were made in

the mold, thus creating Variety Two B molds. This is total speculation on my

part, and I welcome any and all comments.

I MOLD: The story of I mold EC&M's dates back to the 1960's. Jim

Hill of Canyonville, Oregon wrote one of the first price guides on insulators.

Jim sketched drawings of the insulators he put in his book. Due to a lack of

space on the drawings, Jim would depict the embossing in unusual places. For

EC&M's, Jim showed the embossing on the skirt. This placement led collectors

to debate for decades whether or not EC&M's existed with embossing on the

skirt.

Then, in the November 1995 issue of Crown Jewels, Dwayne Anthony announced

the discovery of a cache of perhaps 200 EC&M insulators in Northern

California. The insulators were excavated at the site of a toxic waste cleanup.

Many dozens of them were damaged by heavy equipment. Due to regulations

requiring proper disposal of hazardous materials found at the site, the

insulators reportedly were secretly removed by construction workers. This shroud

of secrecy continues to hamper full disclosure of the find to this day.

Many of

the insulators were B mold styles, or something similar. That is, embossed above

the wire groove as normal with a small upper loop on the ampersand. But Dwayne

reported in his article that 11 EC&M's were found with the embossing on the

skirt!

For classification purposes, I'll identify the skirt embossed EC&M's

as mold style I. The embossing is similar to B molds in that the upper loop of

the ampersand is small.

Colors include yellow green, chartreuse, slate blue,

smoke, and dark charcoal smoke.

Although examples sell for many thousands of

dollars apiece when offered at auction, diverse opinions remain within the

insulator collecting community regarding the authenticity of I mold EC&M's.

J, K, L & M MOLDS: The next four mold styles of EC&M's

show evidence of having been made in a manner completely different than all

other EC&M mold styles. The embossing in each variety was placed into the

mold using a slug plate!

In the discussion on F, G & H molds, it was noted

that a slug plate was apparently used to cover the upside down embossing of the

E mold. But in no traditional mold style was a slug plate used as the method for

creating the embossing.

In a picture on the first page of the color insert

regarding slug plates, you can clearly see lines both above and below the letter

"E". These "mold" lines are not always quite so evident, nor

so strongly embossed. But a close inspection will generally reveal at least some

evidence of the slug plate in these mold styles.

Although there are numerous

other differences between these mold styles and traditional molds, it is the

presence of the slug plate that is the quickest method of distinguishing them.

The thin lines above and below the embossing in J, K, L and M mold styles were

created when molten glass filled the space between the softer metal used in the

slug plate, and the harder metal of the mold itself. In addition to the lines,

there are faint "rivet" marks on either side of the embossing. The

rivets presumably were used to hold the slug plate in place. The

"mold" lines extend all the way to the seam line on each side of the

insulator.

J MOLD: This slug-plated embossing style has a small upper loop in the

ampersand, similar to B molds. The button is on the reverse, and the dome is

squared, also like B molds. However, the embossing in J molds is 74 millimeters

long, compared to 64 millimeters for Variety One B molds and 69 millimeters for

Variety Two B molds.

K MOLD: Studies on EC&M's are a work in progress. The color insert in

this issue was printed a couple of months ago. Today, after handling many more

of these insulators, I would describe the dome shape of K's as sloping, and not

squared. K mold's are very similar to M mold's except for the embossing. See

pictures below.

l MOLD: This slug-plated embossing style also has a large upper loop in the

ampersand, but the button is on the front like a C mold. However, the embossing

is only 61 millimeters long. In C's, the embossing is 75 millimeters long. This

insulator has a sloping shape to the dome, rather than squared or beveled or

rounded like traditional EC&M's.

|

|

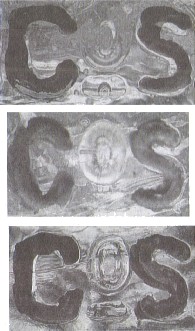

There are notable differences in the shape of the letters "C" and

"S" in mold styles K, L & M.

In K's, top picture, the letters are rounded; the bottom of the "C"

is open; and the start of the "S" is even with the curve below it.

L's, middle, have well rounded, sans-serif letters. The start of the

"S" does not extend as far forward as the curve below it.

In M's, bottom, the "C" and "S" appear to have serifs

(accents). The start of the "S" extends beyond the curve below it.

|

M MOLD: This slug-plated embossing style also has a large upper loop in the

ampersand, but the button is on the reverse like a G mold. The embossing is only

64 millimeters long, compared to 68.

N MOLD: The N mold is a no-name EC&M. It has a CD 123 shape, but lacks the

EC&M embossing. The only embossing are the numbers "54" in

reverse. The embossing is on a large protrusion of glass that extends from mold

line to mold line. It is apparent this item is related to the production of slug

plated EC&M's, except that it was poured without the slug plate in place.

The glass, then, filled the space normally occupied by the slug plate, creating

the raised protrusion. The numerals were probably carved into the mold itself.

J, K, L, M & N COLORS: A few items made in these mold styles are found

in normal aqua colors. But the styles are better known for wild and bright

colors never observed in the traditional molds. Colors include bright orange,

cranberry red, peacock blue, crystal clear, and neodymium purple. They are also

known in cobalt blue, bright green, and black glass green.

Neodymium is an

element that had not yet been discovered at the time EC&M's are generally

believed to have been produced. The element reportedly wasn't used in glass

production until around 1920. Glass makers took a liking to neodymium because of

how it responds to different kinds of light. The neodymium purple shown in the

color insert is almost reddish violent in natural light, but dark purple in

fluorescent light, and nearly pink in incandescent light.

The most common color,

based on the five-dozen or so slug embossed examples I've personally examined,

is black glass green.

VARIED OPINIONS: Mold styles J, K, L, M & N are listed by the National

Insulator Association as "suspected imitations". Certain collectors in

the hobby remain convinced they are genuine. I contacted one person who is a

strong advocate for these pieces. Since he was reportedly involved with them

from shortly after their discovery, I invited him to tell their story in his own

words. He declined, writing in an email that due to legal ramifications,

"no information on the subject will be released at this time."

OTHER MOLDS? Almost certainly other mold styles of EC&M's exist. I've

heard about some but have not seen them. Again, this is a work in progress and

not the final word. If you know of a different EC&M, please send a picture

and description to the editor.

RARITY: Thousands of EC&M's have been found over the years. Still, demand

exceeds the supply. This is due to the fact that few collectors own just one

EC&M. I know one collector who has 80 different (color shades and mold

styles). Another has 150 EC&M's, all of which he considers essential to his

collection even when the colors and mold styles are the same.

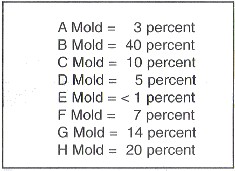

The following chart is intended to give a rough estimate, by proportion, of

how frequently each traditional mold style is encountered.

Editor's Note: This article was intended to be aid to help collectors

identify EC&M insulators by mold style. It's purpose was not to declare one

style or another as imitations. Opposing views, corrections, or additions are

welcome and will be published.

|